How to choose a clutch

The selection of the correct clutch for the intended application is critical to good operation, including the characteristics of (but not limited to:

- clutch feel

- operating temperature range

- wear characteristics / durability

- clamping force

- break-in period

Quite often, the first impulse is to get "too much" clutch. This is often a very big mistake, as there will be compromises in some or all of the operational features listed above.

The first step in identifying what clutch to get is dependent on the characteristics of the car. Ask these questions:

- How much power does the car make?

- How is it used? Street driving or track use? If for racing, what kind of racing?

As we are dealing with BMW applications here, let's use an widely-understood example - the 1992-2004 6-cylinder 3-series. Over this 12 year period comprising two different chassis, we are still dealing with virtually the same fundamental engine and transmission designs. Power ranges from around 190hp to 333hp. Typical bolt-on modifications bring many of the early models up to the 215hp-260hp range and later models around 350hp. Extensive modifications including supercharging or turbocharging bring power to the 350hp-450hp range, with some examples in the 500hp-600hp range. The typical BMW enthusiast uses the car primarily for sporty street driving, and the occasional auto-x or track day. The 3-series is also popular as a heavily-tracked car and dedicated race car. Some see time spent drag racing, whether occasionally or as dedicated drag racers.

So it is apparent that we have a broad range of power and use to contend with.

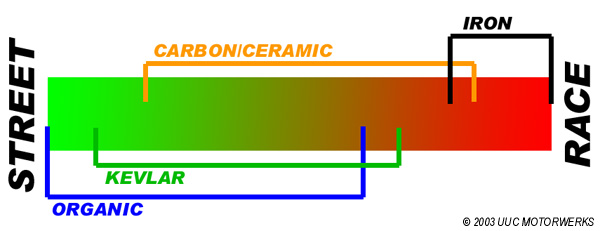

Presented in increasing "aggressiveness", here is a brief overview of clutch compounds, their power handling, and other characteristics:

(note that hp figures are generalized, pressure plate clamping force and torque curves are additional factors)

So it is apparent that we have a broad range of power and use to contend with.

Presented in increasing "aggressiveness", here is a brief overview of clutch compounds, their power handling, and other characteristics:

(note that hp figures are generalized, pressure plate clamping force and torque curves are additional factors)

| organic | |

| CHARACTERISTICS | Metal-fiber woven into "organic" (actually CF aramid with other materials), original-equipment style. Known for smooth engagement, long life, broad operating temperature, minimal-to-no break in period. Will take hard use, somewhat intolerant of repeated abuse (will overheat). Will return to almost full operational condition if overheated. Material is dark brown or black with visible metal fibers. |

| USE | Street-driven cars up to 400hp, auto-x and track use. |

| kevlar | |

| CHARACTERISTICS | A high-durability material more resistant to hard use. Engagement is similar to organic, but may glaze slightly in stop-and-go traffic, resulting in slippage until worn clean when used hard again. Higher temp range in general, but can be ruined from overheating - will not return to original characteristics if "cooked". Has a break-in period of 500-1000 miles during which slippage may occur. Care must be taken during this period not to overheat from excessive slipping. Material is uniform yellow/green and may look slightly fuzzy when new. |

| USE | Street-driven track cars up to 500hp, auto-x and heavy track use. Will take hard use, intolerant of abuse (will overheat and not recover completely). Due to the unforgiving nature of Kevlar, it is not recommended for street cars, especially those that see frequent stop-and-go traffic which will cause surface glazing of the clutch. |

| segmented kevlar | |

| CHARACTERISTICS | Same material and characteristics as solid kevlar above, but segmented (blocks or sections missing) for better heat dissipation. New generation of kevlar offered by UUC is resistant to glazing and is an excellent choice for smooth operation in high-powered cars or those equipped with SMG transmissions. |

| USE | Street-driven track cars up to 650hp, auto-x, and heavy track use. |

| hybrid carbon/ceramic/organic | |

| CHARACTERISTICS | Organic material on one side and a segmented carbon or ceramic material on the other. The idea is that the organic side will help smooth the engagement, reducing the shuddering from the segmented side. Engagement is same as organic, but still with shuddering. Temperature and hp range is identical to organic. Carbon/ceramic side will wear flywheel or pressure plate surface faster and will wear out faster in traffic situations. Material is organic on one side (described above) and segmented or completely separate pucks (described below) on the other. |

| USE | Can be used in same situations as standard organic. The "hybrid" design appears to be more of a marketing gimmick rather than an actual performance advantage. Some brands are poorly designed and wear unevenly due to flexation of the clutch disk. For examples of hybrid failure, click here. |

| carbon/ceramic | |

| CHARACTERISTICS | Very high temperature materials, usually only found on multi-puck disks. Will accommodate 500hp+ Engagement is more abrupt. Will wear flywheel surface faster, especially in traffic situations. Carbon is slightly more durable and flywheel-friendly, ceramic has a higher temp range. Multi-puck design may result in slight shuddering or "stepped" engagement when used in traffic situations, although many users report completely acceptable operation. Material is any of several light hues - gray, pink, brown. |

| USE | Street/strip applications for drag-racing and heavy track use cars up to 500hp. Will take very hard use, suitable for extreme-clamping applications. |

| sintered iron | |

| CHARACTERISTICS | Extremely high temperature material. Will accommodate 700hp+ Engagement is on or off. Requires special flywheel surface. Material is metallic gray. |

| USE | Strictly for high-horsepower endurance racing. With correct pressure plate, capable of extremely high clamping force. Engagement is like a switch, either on or off. Does not work well when cold. High-durability flywheel surface required, standard flywheels will be destroyed quickly. |

Back to our original question, how to choose? The answer depends on the answers to the two basic questions asked earlier regarding intended use of the car and power output. Based on the answers, this gauge will help the decision:

To repeat the important point, do not buy more clutch than you need.

A simple organic disk will handle a wide variety of use - including street use, auto-x, and even true racing. In fact, SCCA ITS racing rules require a standard OE-spec organic disk. UUC has tested organic disks to reliably handle up to 475hp in long-term street use. M3s regularly run through several auto-x seasons without problems.

A kevlar disk is a good choice for a heavily-tracked or road-raced cars, especially with forced induction.

Carbon/ceramic should be left to high-power cars that see lots of drag racing, or are dedicated track/drag cars.

Sintered iron clutch disks are strictly for endurance racing.

A simple organic disk will handle a wide variety of use - including street use, auto-x, and even true racing. In fact, SCCA ITS racing rules require a standard OE-spec organic disk. UUC has tested organic disks to reliably handle up to 475hp in long-term street use. M3s regularly run through several auto-x seasons without problems.

A kevlar disk is a good choice for a heavily-tracked or road-raced cars, especially with forced induction.

Carbon/ceramic should be left to high-power cars that see lots of drag racing, or are dedicated track/drag cars.

Sintered iron clutch disks are strictly for endurance racing.

(c) 2003 UUC Motorwerks ï http://www.uucmotorwerks.com ï 908-874-9092

No comments:

Post a Comment